It’s a wonderful experience working with the entire KVF team! They go above and beyond with their customer service and their turnaround/lead times! The business relationship that has been built with KVF is appreciated. Keep up the great work!

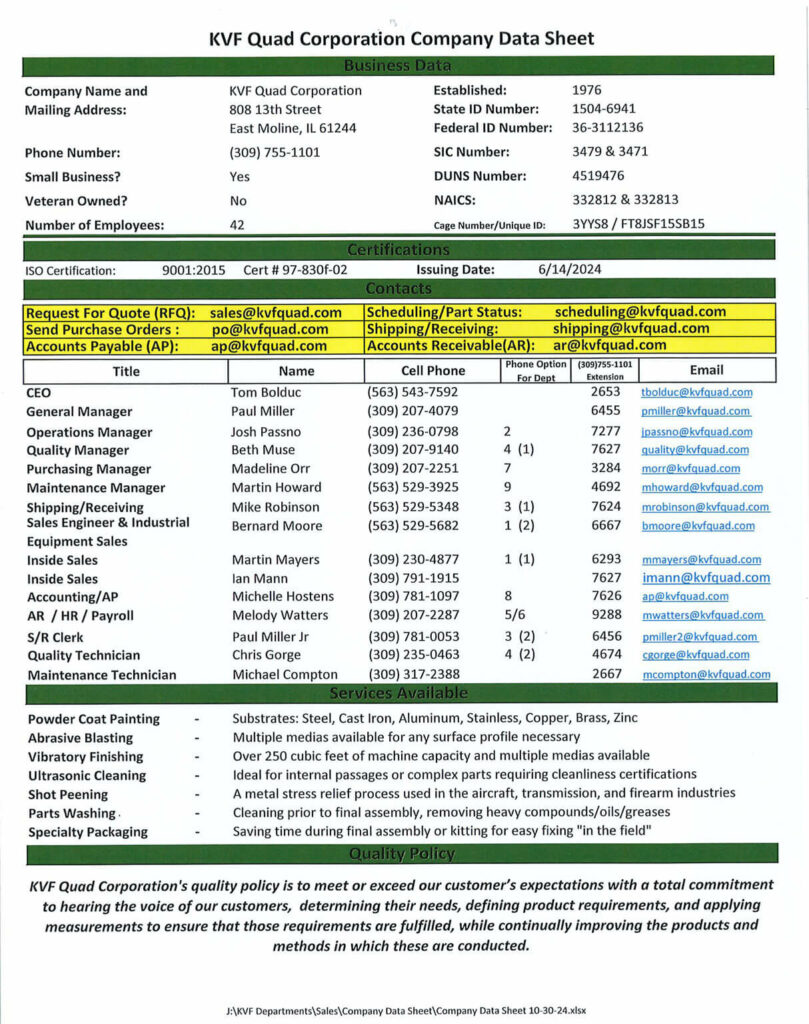

KVF Quad Corporation

KVF Quad Corporation is a top supplier in mechanical metal finishing and powder coat painting in the Midwest Region. Serving Illinois, Iowa, Missouri and Wisconsin. KVF has the capability to process small parts to large assemblies, never turning away from any challenge.

Marcie Mills

Lisa Wertzbaugher

KVF Quad has been a strategic partner for us in pursuing new business. We work together as a team to launch to new projects.

Mike Baugh

I would refer them to anyone who needs powder coating or shot blasting done. We send many parts of all shape and sizes to them and get great results. Their quality, lead time, customer service and pricing is great. From when they receive our parts to when they send them back the service is great.

Powder Coating

KVF Quad Corporation is the Quad Cities expert on powder coat painting. Our paint application facilities can adapt to a wide range of size, shape, quantity and special components to satisfy the complex needs of our customers.

Abrasive Blast Finishing

Abrasive blast finishing (air blasting) cleans and removes scale, rust, marking, previous coatings or weld splatter from component surfaces by propelling media using compressed air.

Shot Blasting

Shot blasting is an aggressive process used to generate anchor surface, remove tight mill scale, previous coatings or foundry slag, and leave components with a uniform exterior surface finish.

Vibratory Finishing

Using a variety of equipment types and sizes plus an array of media types, KVF Quad’s vibratory finishing services yield exceptional results in mass finishing customer parts.

Ultrasonic Cleaning

In parts cleaning application, ultrasonic vibrations generate sound waves in a cleaning solution leaving parts exceptionally clean and exceeding many industry standards.

Parts Cleaning

Parts cleaning is essential to many industrial processes as a prelude to surface finishing or to protect sensitive components. KVF Quad offers abrasive and nonabrasive cleaning options as well as a five-stage wash for our customers.

Shot Peening

Shot peening has many useful applications across a handful of industries, most notably increasing the life span of a part. This process produces a compressive residual stress layer of metal on parts such as gears, cams and camshafts, clutch springs, coil springs, connecting rods, crankshafts, gearwheels, and turbine blades.

Testing Services at KVF Quad Corporation

Many of our clients require certification or part finishing that meets industry standards. At KVF Quad, we help our clients meet required criteria in many industries, including agriculture, aerospace, automotive, government, medical, construction equipment, and more.

Thermal Paint Removal

A more effective and eco-friendly option to remove paint from parts, thermal paint removal at KVF Quad can accommodate a multitude of part types and sizes. Designed to reduce dependence on costly and dangerous chemical stripping compounds, thermal heat cleaning ovens effectively reduce all potential waste to ash.

Other Product Services

At KVF Quad, we offer a variety of added services beyond metal finishing to relieve our customers of extra steps or hiring another company to complete minor tasks. These services are easily paired with metal finishing projects and can help create a higher quality, longer lasting product for the customer.

Laser Oxide Removal

As thermal cutting processes in the metalworking industry increases, the need to remove the oxidation produced by those processes has also increased. Laser oxide removal is a great solution for customers needing clean, quality parts.

Equipment Sales

KVF Quad Quality

Since 1997, KVF Quad Corporation’s quality management system has been ISO Certified, and continues to maintain our qualifications to the most current revisions.

Quality processes and services are accomplished through:

- Monitoring customer satisfaction

- Using quality suppliers and products

- Practicing continual improvement policies

- Minimizing rework and waste

- FMEA (Failure Mode and Effective Analysis)

KVF’s quality policy and motto “To meet or exceed our customer’s expectations” reflects how actions bear testimony towards our total commitment. Listening to our customer, determining needs, defining product requirements and applying measures ensure our processes provide consistent uniform results and continuous customer satisfaction.

Our ISO registrar, ITS Intertek Services, assesses our current certification for conformity annually. External, internal and ‘customer’ conducted second part audit results are available for review upon request.

KVF Quad: Who We Are

The KVF History

Highly Qualified Team